| <<< Ender 3 S1 Pro | Genius Pro >>> |

CRUX 1 from Tronxy

The gadget in moving pictures with audio

You can buy the Tronxy CRUX 1 on:

Amazon US

Amazon UK

Amazon DE

Or by via the online shop of Tronxy and get 2% off with the code HOITG.

By purchasing via the specified affiliate links, you support HOITG without any additional costs for you - thanks!

How Open Is This Gadget?

| Category | Remark | Info |

|---|---|---|

| Firmware |

Uses Marlin firmware, modified source code is asvailable. |

? |

| Software |

Machine data can be processed with common open source software that generates Gcode. |

? |

| Hardware |

All parts are very easy to replace, common screw types, common components. |

? |

| Electronics |

Mainboard uses a standard STM32 microcontroller. Stepper motor drivers are soldered to the mainboard. |

? |

| Website |

Website of Tronxy offers firmware downloads. The Source code of the modified Marlin firmware was sent to me on request. |

? |

| Patente |

Tronxy doesn't claim patents on the CRUX 1. |

? |

The Gadget in detail

Figure 1:The CRUX 1 from Tronxy I is a very compact 3D printer. The print volume is 180x180x170mm and with the dimensions 40x44x41cm including filament spool, the CRUX1 fits on any desk or finds a place even on a crowded workbench. With the small carrying handle on top of the device, the printer can be quickly put away after work is done.

A filament sensor and the ability to continue printing after a power failure reduce the risk of failed prints.

In contrast to some competitors, Tronxy follows the rules of the GPL license of the Marlin firmware and sent me the source code of the modified version by email on request. This is totally in the spirit of "How Open Is This Gadget?".

Technical data

| Category | Value | Remark |

|---|---|---|

| Print volume | 160x160x170mm | With the print bed adjusted to a low position and by ignoring the clamps that attach the glass plate to the print bed, 180x180x180mm are possible. |

| Dimensions | 400x440x410mm | Including filament spool. |

| Print bed heating | Up to 110°C | 100°C after 7 minutes |

| Hotend | Up to 275°C | |

| Firmware | Marlin | |

| Other |

Filament sensor Resume print after power failure Print data can be sent via micro SD card, USB stick or USB interface. |

Package contents

Figure 2:The package includes the tools for assembling the components, replacing the 0.4mm nozzle and adjusting the mechanics. The short assembly instructions is included in printed form and are also located on the micro SD card that ships with the printer.

Assembly

Figure 3:The CRUX1 is delivered almost fully assembled. Only the frame has to be mounted on the base, the handle as well as the filament holder and the glass plate have to be attached.

Mechanics

Figure 4:The CRUX1 has a direct extruder with the components not being hidden under a cover - everything is clearly visible. The Teflon tube runs to the filament sensor at the end of the X-axis and ensures that the plastic wire is fed in smoothly.

The X-axis is guided by steel rollers with ball bearings along a steel bar, which in turn is attached to 20x20mm extruded aluminum. The print bed moves along the Y-axis following the same design principle.

The Z-axis is guided by plastic rollers with ball bearings, the extruded aluminum here has the dimensions 20x40mm. The backlash of the plastic rollers can be minimized by turning an eccentric nut.

The belt tension of the X-axis can be easily adjusted using a small hand wheel. The Y-axis belt tension is adjusted by moving the stepper motor, which is mounted on slotted holes.

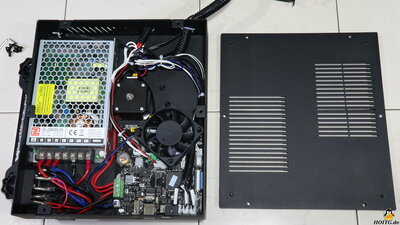

Electronics

Figure 5:Inside the base, the electronic components are densely packed, but the arrangement looks tidy.

The power supply provides an output voltage of 24V at up to 10A, corresponding to 240W.

A microcontroller type STM32, on which the firmware "Marlin" runs, is placed on the mainboard. The modified Marlin source code was sent to me immediately upon request by email - that's totally in the spirit of "How Open Is This Gadget?".

The drivers for the 4 stepper motors are soldered to the circuit board.

Mechanical end switches are mounted on all three axes

Test prints

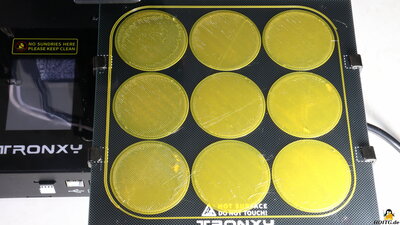

The G-Code and stl files of all test prints done with the Tronxy CRUX 1 are available as download package (11.2MB).Figure 6:

The first print job is to check the flatness of the build plate:

9 discs are printed, each with a diameter of 50mm and a height of 0.2mm.

All details on the test procedure.

Figure 7:

3D Benchy with optimal settings

All details on the test procedure.

Bei den folgenden Schnelldrucken der Benchy kommt es mit zunehmender Geschwindigkeit weniger darauf an zu sehen, was schlecht ist, sondern vielmehr, was noch gut gedruckt wird.

Details hierzu gibt's in dem Kapitel zum Testverfahren.

Figure 8:

3D Benchy with 60mm/s

All details on the test procedure.

Figure 9:

3D Benchy with 90mm/s

All details on the test procedure.

Figure 10:

3D Benchy with 120mm/s

Print time: 32 minutes

All details on the test procedure.

Figure 11:

In order to print large objects quickly, as much plastic as possible must be extruded per unit of time, which is tested here.

Although the CRUX1 has a direct extruder, it comes with a stepper motor with no too high torque and the nozzle is a standard version. Therefore, the material throughput is obviously not the CRUX1's prime discipline, which is not quite as relevant for a printer with a small print volume.

Layer height: 0.4mm

Extrusion width: 0.7mm

A, F, K = 30mm/s

B, G, L = 60mm/s

C, H, M = 70mm/s

D, I, N = 80mm/s

E, J, O = 90mm/s

All details on the test procedure.

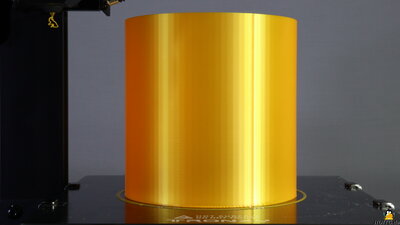

Figure 12:

Large 3D Benchy with optimal speed settings

Benchy enlarged to 330% (192x102x158mm)

Print time: 7.5 Stunden

All details on the test procedure.

My conclusion

The Tronxy CRUX 1 is a very compact printer. To my mind, smaller is better, especially for beginners, and since most prints aren't really large, a small, second machine is often a helpful tool for a quick project. The machine is sturdy and all components are easily accessible. Leveling of the print bed is done in the classic way by using a sheet of paper to adjust the gap between build plate and nozzle. Since the print head can be moved to the corner points quickly via the printer menu and due to the large handwheels, this can be done more quickly than with many printers that have an autolevel function.As far as I know, Tronxy does not claim any patents on the CRUX 1 and the modified source code of the "Marlin" firmware was sent to me immediately upon request.

A good 3D printer that has everything you need for printing and no unnecessary frills.

| <<< Ender 3 S1 Pro | Genius Pro >>> |