| <<< FlyingBear LaserMan | CNC machines >>> |

LaserMaster 2 2S from Ortur

The gadget in moving pictures with sound

You can buy the LaserMaster 2 2S via my affiliate partner zBanx in the online shop of Ortur.

By purchasing via the specified affiliate link, you support my channel without any additional costs for you - thanks!

How Open Is This Gadget?

| Category | Remark | Info |

|---|---|---|

| Firmware |

Firmware is based on the open source software grbl. |

? |

| Software |

Machine data can be processed with common open source software to generate Gcode. |

? |

| Hardware |

The components are very easy to replace, common screw types, nothing is glued. |

? |

| Elektronik |

Mainboard uses a common ESP32 microcontroller. |

? |

| Website |

The website lists very precise information about the materials that can be processed. Ortur publishes the modified source code of the grbl based firmware on Github. |

? |

About the gadget

Figure 1:The LaserMaster 2 2S from Ortur can process workpieces with a base area of up to 39.5x41cm. The two axes are guided along extruded aluminum of the dimensions 20x20mm with the help of plastic rollers on metal ball-bearings. The backlash can be minimized via eccentric nuts using the included wrench. The axes are driven via timing belts. The two pulleys of the Y-axis are connected via a round rod and so driven by only one stepper motor. The advantage of this construction is that the two ends of the X-axis cannot be moved independently, so the mechanics wont get misaligned over time.

Technical Specs

| Category | Value | Remark |

|---|---|---|

| Work area | 395x410mm | |

| Dimensions | 57x60x20cm | |

| Laser module |

Laser power: 5.5W Input power: 16W Focal length: 30mm Wavelength: 450nm |

Type LU2-4-SF |

| End schwitches | X, Y at zero point | |

| Energy consumption |

With laser at 100%: 30W Air pump: 16W |

Power supply: 24V at up to 2A Air pump is an option. Power supply air pump: 12V at up to 2A. |

Package contents

Figure 2:Included in the package are a power supply that delivers an output voltage 24V at up to 2A, a USB cable for data transfer from a PC, tools for the assembly, and some materials that can be engraved with the machine.

Also included are safety goggles, an you should make sure to wear these while operating the device!

Assembly

Figure 3:There isn't too much to be done:

Assembling the frame and the wiring is done quickly.

Electronics

Figure 4:A microprocessor type ESP32 is placed on the mainboard running the firmware GRBL. A socket for the power supply, the USB socket for data transmission and a socket for an offline controller are the interfaces to the world outside. A power button and a second button for resetting the firmware can be seen on the right of the mainboard. The front and back of the circuit board are labeled perfectly.

The power supply delivers an output voltage of 24V at up to 2A, which is 48W.

Laser module

Figure 5:The laser module is type LU2-4-SF - "SF" stands for "Short Focus", meaning a focal length of 30mm. The maximum laser power delivered by the built-in diode is 5.5W while consuming an electrical input power of around 16W.

Extras

Figure 6:In addition to various laser machines, Ortur also offers plenty of accessories for these devices - extras I received are a metal grid for laser cutting and an electric pump that can be used to blow a jet of air onto the surface for better results. The power supply of the air pump delivers 12V at up to 2A, which is 24W.

Tests

Figure 7:Cutting cardboard and plywood:

A-D: 2mm single cardboard, front and back

E+F: 4mm plywood, front and back

G+H: 4mm plywood, front and back, with "Air Assist" and metal grid

I: Back without and with "Air Assist" and metal grid

J-L: 2mm cardboard, stack of 4

The cutting speed for the 2mm cardboard was 60mm/min

Details on the testprocedure.

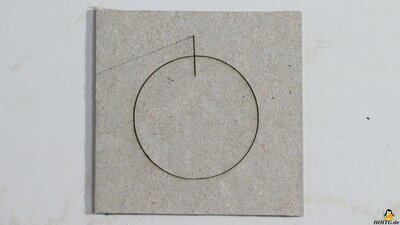

Figure 8:

Engraving bitmap and vector graphics:

Details on the test procedure.

Figure 9:

Engraving the included sample materials:

The laser cannot engrave bare aluminum because this material has a too good thermal conductivity. Only the colored coating is evaporated from the bone shaped aluminum. With that, the engraving is clearly visible.

My conclusion

Ortur's LaserMaster 2 2S has sparked a long-running dispute over violation of grbl's GPL V3 license, on which Ortur's firmware is based. Like almost all manufacturers of cheap laser machines up to this point in time, Ortur also refused to publish the modified source code. On "How Open Is This Gadget?" I also test closed source devices, but when open source licenses are trampled on, I don't know any mercy. Hackaday (thanks, Elliot) acted as a powerful partner in this argument, and finally Ortur admitted his failure. The source code is now available on Github. Now that this dispute came to an end, the LaserMAster2 2S is worth buying.| <<< FlyingBear LaserMan | CNC machines >>> |