| <<< Laser cutters | xTool D1 Pro 20W >>> |

Test procedures laser cutters

General

The videos on "How Open Is This Gadget" show the functions of the laser cutters and give you an impression of the quality of the mechanics in moving pictures. However, I intentionally do not give any comments on the quality delivered in the videos of the tested machines! I want to leave that up to you, because only you know what you expect from a laser cutter. Furthermore, slogans such as "The best laser cutter at X price" are usually obsolete just a few days after a video has appeared, since there are many manufacturers in the middle to lower price range, all competing for the lowest price.So have a close look at the high-resolution photos taken of the test results and the mechanics of the machine to get an own mpression.

For all tests there is: If you can't realy see any differences between different machines, then consider them equal and focus on other things, such as the openness of hardware and software! Just don't start interpreting the smallest differences in the pictures, that's just not relevant in practice. Keep your feet on the ground and don't listen to any self-proclaimed experts (myself included).

Both the test patterns and the Python scripts that I use to transfer the data to the laser cutter are available for download.

Laser modules

The results that can be achieved with a laser cutter depend on the installed laser module. Especially in the field of cheap laser cutters, the various manufacturers all use more or less the same laser modules. What makes the real difference is the laser output power a module delivers. With the same laser power, the laser modules are mostly equivalent. It should be noted that some manufacturers propagate very dubious numerical values! So if an unusually high laser power is advertised for the price range, the manufacturer is most likely using some fancy values!As the output power is what makes a difference, this is tested with the:

Cutting performance

|

|

| 1920x1080 | Full res |

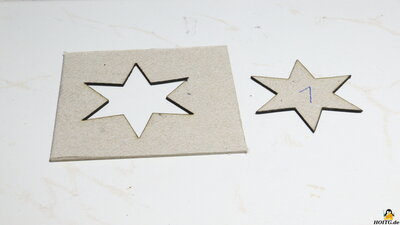

As a test material for the cutting performance, I use 2mm cardboard. This has a more homogeneous structure than e.g. plywood. A 6-pointed star is cut out. In this test, the laser is set to 80% of maximum power and the cutting speed is adjusted so that two of the cardboard are cut cleanly. The higher the cutting performance of the loader module, the higher the speed can be set.

Engraving

|

|

| 1920x1080 | Full res |

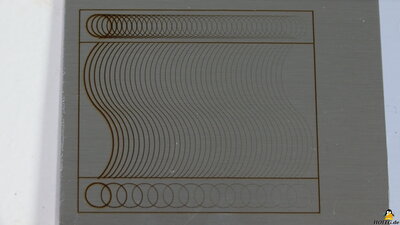

A vector graphic is engraved on stainless steel. Stainless steel because this material dissipates heat less well than ordinary steel and the engraving is more visible. The test pattern consists of wavy lines and circles. The laser power is set to 80% and the speed gradually increased from left to right, making the engraving less and less visible.

On the far left it starts at 180mm/min (3mm/s) and increases the speed by 60mm/min (1mm/s) with each step.

With 5W lasers, 40 steps up to 2580mm/min (43mm/s), with 20W lasers 80 steps up to 4980mm/min (83mm/s). The deeper and finer the lines, the better the laser. The lines should also be as smooth as possible, the circles should be round.

Specials

|

|

| 1920x1080 | Full res |

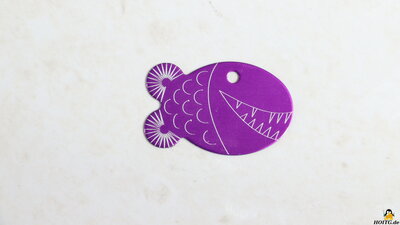

If the manufacturer supplies any sample materials, I also cut or engrave some of them as an extra.

| <<< Laser cutters | xTool D1 Pro 20W >>> |