| <<< Test procedures CNC machines | Tools >>> |

CNC 3018 Pro Max from Mostics

The gadget in moving pictures with audio

You can buy the 3018 Pro Max from Mostics on Amazon.com

By purchasing via the specified affiliate link, you support HOITG without any additional costs for you - thanks!

How Open Is This Gadget?

| Category | Remark | Info |

|---|---|---|

| Firmware |

Uses grbl as Firmware. The manufacturer gives no info on compiling and flashing of firmware. Firmware offline controllers unknown! |

? |

| Software |

Machine data can be processed with common open source software to generate Gcode. |

? |

| Hardware |

The components are very easy to replace, common screw types, nothing is glued. |

? |

| Elektronik |

Main board works with an ATmega328P, can be replaced by an Arduino UNO with CNC shield. Offline Controller is a special part that can probably only be obtained from the manufacturer. |

? |

| Website |

Mostics sells the products exclusively via the Amazon Store, but inquiries are answered by email. The grbl source code is not linked, nor is there any information about any changes to the source code. |

? |

The gadget in detail

Figure 1:The CNC milling machine 3018 Pro Max from Mostics is suitable for milling wood or plastics. How good can be seen in the examples down on this page. The frame is made entirely of aluminum. The X and Y axes are guided along 10mm round steel using linear ball bearings. The round steel has a diameter of 8m on the Z-axis, since the travel distance is only 55mm. The system is not free from backlash, but it is quite solid.

An emergency stop switch is located on the right side of the frame. Two plexiglass panes on the sides don't offer full protection, but at least keep chips from flying in all directions.

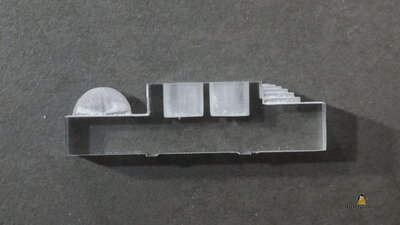

An alligator clip and metal cylinder can be used to measure the Z position of the cutting tool above the router table, which is important after a tool change.

The router table is made of 20mm extruded aluminum with 4 grooves. Workpieces can be easily fixed using the screws, metal plates and wing nuts.

The offline controller enables operation without a connected computer, data is transferred in G-code format via SD card. All 3 axes can be controlled at a push of a button.

The axes can also be moved manually using the handwheels.

The mainboard is based on an ATmega328P running the open source firmware grbl.

The well-insulated 24V/10A power supply ensures that there is no danger of coming into contact with mains voltage.

Technical data

| Category | Value | Remark |

|---|---|---|

| Work area | 294x132x49mm | Without the end switches 300x155x55mm. |

| Dimensions | 450x405x320mm | |

| Spindel | 200W, 24 V, 10000U/min; | |

| End switches | X, Y, Z | Switches on both ends of each axis, switched in parallel. |

| Energy consumption |

2-3W in stand by about 40W with running motors |

Using the offline controller, no extra power is required for a computer during operation. |

Package contents

Figure 2:The 3018 Pro Max from Mostics is delivered largely pre-assembled in a well-padded box. A set of hexagonal tools is sufficient for assembly and two open-end wrenches are used to change tools on the spindle.

10 pieces of 30° V-bits and two 2mm milling cutters (4mm shaft) ship with the CNC along with two ER11 collets with 3.175 and 4mm mounts.

The USB stick contains the assembly instructions as a PDF and there is a micro SD card with the appropriate adapter for data transfer via the offline controller.

Assembly

Figure 3:Not many parts have to be assembled:

For the mechanics, the frame and base must be screwed together with 8 screws of 16mm length, and the rubber feet and side panels must be attached.

For the electronics, the main circuit board must be screwed to the frame and the cables for the stepper motors and the spindle must be laid. The cables have to be attached with spiral hoses and cable ties.

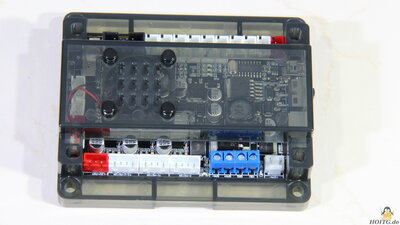

Electronics

Figure 4:The mainboard is based on an ATmega328P running the firmware grbl. All connectors are perfectly marked on the circuit board. A small fan ensures that the components are adequately cooled.

The offline controller is based on an STM32 microcontroller, the source code of the firmware is not available.

The power supply with an output voltage of 24V at up to 10A is well insulated and has large heat sinks inside.

Tests

Figure 5:Milling beech wood with a 30° V-bit.

Details on the test procedure

Figure 6:

Milling Acrylic plastic with a 2.5mm 2-flutes cutter.

The effects of backlash are described in the details on the test procedure.

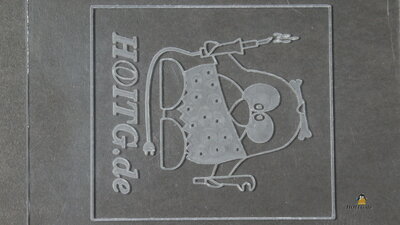

Figure 7:

Engraving 2mm Plexi glass with a 30° V-bit.

Details on the test procedure.

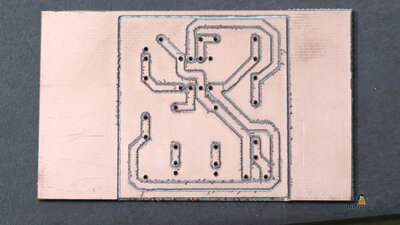

Figure 7:

Isolation milling of a circuit board with a 30° V bit. The holes were drilled with a 1mm drill.

On picture C the burrs of the copper tracks have been removed with 1000 grit sandpaper.

Details on the test procedure.

My conclusion

In terms of open source, the approach of using grbl as firmware is very good, but there is no open source firmware for the offline controller. The hardware is bolted, parts can be easily replaced.The 3018 Pro Max from Mostics is well suited for working with the 30° V bit, which does not generate excessive lateral forces when removing material. The engravings in beech wood and plexiglass work well. Insulation milling of circuit boards is feasible, but not without reworking, since the paths are not really smooth.

When 3D milling acrylic glass with a 2.5mm milling cutter, the mechanic reaches it's limit. Harder materials such as aluminum cannot be machined.

A machine with a robust but not backlash-free mechanics to get started with CNC milling, with which you can learn the basics of the steps from a 3D model or a 2D sketch or graphic to G-code machine commands.

| <<< Test procedures CNC machines | Tools >>> |