| <<< Ceramic printers | SLS printers >>> |

Moore 1 from Tronxy

The gadget in moving pictures with audio

You can buy the Tronxy CRUX 1 on:

Amazon US

Amazon DE

Or by via the online shop of Tronxy.

By purchasing via the specified affiliate links, you support HOITG without any additional costs for you - thanks!

How Open Is This Gadget?

| Category | remark | Info |

|---|---|---|

| Firmware |

Frimware is Closed Source |

? |

| Software |

Machine data can be processed with common open source software that generates Gcode. |

? |

| Hardware |

All parts are very easy to replace, common screw types, common components. |

? |

| Electronics |

Mainboard uses a standard STM32 microcontroller. Stepper motor drivers are soldered to the mainboard. |

? |

| Website |

Website of Tronxy offers firmware downloads. |

? |

| Patents |

Tronxy doesn't claim patents on the CRUX 1. |

? |

The Gadget in detail

Figure 1:With the TronXY Moore 1 I received my first 3D printer for clay and similar ceramic materials. Compared to classic pottery or modeling these materials can be shaped in a completely new way with the device. Of course, the printer can only be used to produce blanks that have to be fired in a subsequent process in order to obtain ready-to-use ceramics. The Moore 1 is a fairly compact device that occupies little space on your workbench and can be quickly put away after use.

Technical data

| Category | Value | Remark |

|---|---|---|

| Print volume | 180x180x180mm | |

| Dimensions | 355x252x410mm | Without the clay storage extruding mechanics |

| Firmware | Closed Source | |

| Other |

Print data can be sent via micro SD card, USB stick or USB interface. |

Package contents

Figure 2:The delivery includes the tools needed for the assembly, as well as accessories and spare parts.

Assembly

Figure 3:The Moore 1 is delivered almost completely assembled. Only the mechanism for feeding the material has to be assembled from a few parts, the extruder must be attached to the X-axis and a few cables have to be plugged in.

Mechanics

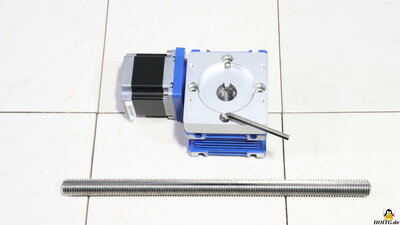

Figure 4:The axes are guided by steel rollers along round steel rods. The X and Y axes are driven by timing belts, the tension of which is adjusted by moving the Y axis motor or the deflection roller on the X-axis. The Z axis is driven via a spindle. If everything is adjusted correctly, all axes run smoothly. The maximum working area is 18x18x18cm.

The extrusion takes place in two parts:

The large extruder motor uses a piston to press the material from the storage container through a transparent hose towards the print head. There is a conveying screw in the print head that then presses the material out of the nozzle.

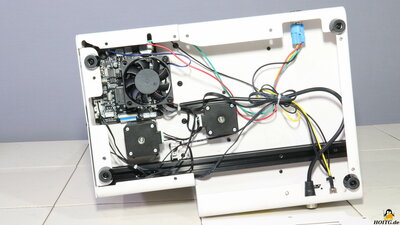

Electronics

Figure 5:The mainboard is located in the base of the printer. The stepper motor drivers are soldered to the circuit board. A total of 5 pieces is required: one each for the 3 axes and the other two for the material feed and the extruder.

The microcontroller is of type STM32.

The power supply delivers an output voltage of 24V at up to 4A, corresponding to 96W.

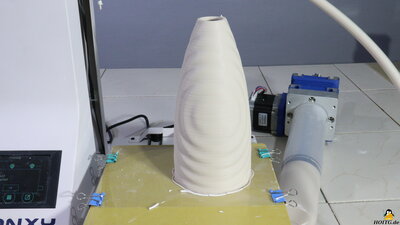

Test prints

The test prints were created with G-Code files that were on the included Micro SD card.Abbildung 6:

File "Vase.gcode".

Abbildung 7:

File "Corrugated vase.gcode".

Abbildung 8:

File "Sashimi vase.gcode".

I printed this and the following two objects using an overhead film on the build plate, which turned out to be a mistake!

The clay shrinks when it dries in the air and the overhead film cannot shrink in the same way. Therefore, stress cracks appear at the bottom of the vase, as can be seen in the last photo in the series. It is therefore essential to use the thin cling film on top of the build plate!

Abbildung 9:

Datei "Water drop pattern vase (high).gcode".

Abbildung 10:

Datei "Bubble bowl.gcode".

My conclusion

The Moore 1 from Tronxy is a compact, affordable ceramic printer that's great for getting started with the world of machine-controlled pottery. There is hardly a more environmentally friendly and recyclable material for 3D printing than clay - so you can experiment without harming your environment.| <<< Ceramic printers | SLS printers >>> |